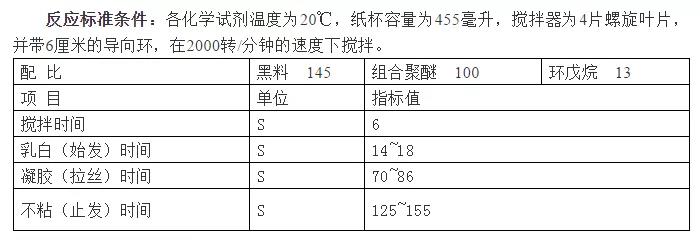

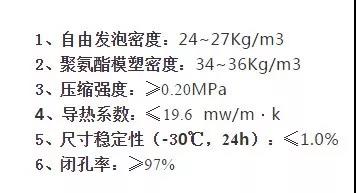

01 raw materials for polyurethane production 3. Foaming agent: in polyurethane foaming, the main function of foaming agent is to produce gas, forming small bubbles with uniform distribution in polyurethane. Foaming agent itself does not participate in the chemical reaction between polyisocyanate and composite polyether. The foaming process using freon (such as R11, R12) as foaming agent is called fluorinated foaming. The foaming process without freon is called fluorine-free foaming. Such as cyclopentane foaming.。 02 foaming process principle Through the injection gun head of the high-pressure foaming machine, the black material and the white material are mixed with the pre mixture of cyclopentane, and injected into the interlayer between the shell and the inner tank of the box body or the door body. At a certain temperature, polyisocyanate (isocyanate (- NCO) and polyether (hydroxy (- OH)) react with catalyst to form polyurethane, and release a lot of heat at the same time. At this time, the foaming agent (cyclopentane) premixed in the combined polyether is continuously vaporized to make the polyurethane expand and fill the gap between the shell and the inner tank. Chemical reaction formula nO=C=N—R—N=C=O + n HO—R’—OH ------->—( OC—NH—R—NH—COO — R’—O —)n 03 Control of process parameters of cyclopentane foaming Ratio of black material to white material: black material to white material to cyclopentane = 145:100:11.5 04 Reaction speed parameters 05 Polyurethane foam performance requirements 06 Common problems of polyurethane foaming and Its Solutions We respect originality. The copyright of the materials with beautiful pictures belongs to the original author. Some articles cannot be contacted with the original author due to various reasons. If copyright issues are involved, please contact us and deal with them immediately. Address: Longzhen Avenue, Longshan Industrial Zone, Cixi, Ningbo Marketing Center: 1308, Yaojiang Xindu, Hongtang street, Jiangbei, Ningbo Tel: +860574-86501282-0 83096225 83096226 Web:http://zy-pigment.en.alibaba.com/

1. Black material: the scientific name of black material is polyisocyanate, because it is a black viscous liquid, so it is commonly known as black material. The main varieties of polyisocyanates are MDI, TDI and PAPI, of which MDI (two phenyl methane diisocyanate) is used for the production of polyurethane foam in refrigerators.

2, white: industrial production of polyurethane foam in refrigerators, usually combined polyether polyols, catalysts, foam stabilizer mixed, this mixture is a white viscous liquid, commonly known as white material.

(1) combined polyether polyols: polyols used in refrigerator polyurethane foam are polyether polyols.

(2) Catalyst: the main function of catalyst is to accelerate the formation of polyurethane, shorten the curing time and improve the foaming quality.

(3) foam catalyst: the main function of foam stabilizer is to ensure the smooth reaction of the system, and to promote the nucleation of bubbles, to improve the stability of the bubble wall, to make the product holes evenly and fine, and to have good mechanical properties. Although the amount of stabilizer is not large, it has great influence on foam structure, physical properties and manufacturing process.

Temperature of foaming stock solution: the temperature of black material and white material shall be controlled at 18 ~ 25 ℃

Mold temperature: 40 ± 5 ℃

Box preheating furnace temperature: 35 ~ 50 ℃, foaming furnace temperature: 35 ~ 55 ℃.

Injection pressure: the injection pressure of black material and white material is controlled at 13 ~ 16MPa.

Aging time: ≥ 6min

Fax: +860574-86501283