>news

Your current location:

home>news

Talk about the production process and formula of several special polyurethane foams

page view:5522 time:[2020-06-29]

Color paste, as the main auxiliary agent used in polyurethane foaming, is widely used in various polyurethane materials. Our factory, as a professional polyurethane color paste manufacturer in East China, produces color pastes with high color concentration, good fluidity, large additions without affecting foaming, bright colors, and strong weather resistance......

Abstract: This article introduces the basic characteristics, physical properties and applications of polyurethane hydrophilic foam, non-yellowing foam and microcellular foam, and describes the basic ideas of their commonly used raw materials, processes, formulas and formula design.Keywords: polyurethane, hydrophilic foam, non-yellowing foam, microcellular foam, formulation designAbout the author: Jiang Shuhui, born in Suzhou in 1953, a senior engineer in Suzhou, Anhui, has been engaged in polyurethane material production and R&D for 38 years. In the following year, he has been doing polyurethane technology development for many years in Suzhou Yitong Polyurethane Company and Zhejiang Huafeng Group Shanghai New Materials Research Institute.Polyurethane flexible foam refers to a porous or reticulated foam (sponge) material that has a certain elasticity and is relatively soft. Its outstanding properties are softness, good rebound, sound absorption, ventilation, insulation, cushioning, energy absorption, etc., and according to different The application areas also have various characteristics.Polyurethane flexible foam has been industrially produced since Bayer's polyester flexible foam (sponge) in 1952. After more than 60 years of development, it has been widely used in all aspects of people's daily life and many industrial fields. At present, domestic soft foam The actual output is estimated at more than 3 million tons. The main types of products are shockproof materials, sound insulation materials, filter materials, thermal insulation materials, packaging materials, decorative materials, clothing materials, etc. In terms of production types alone, flexible polyurethane foams mainly include: block foams (common sponges), high-resilience molded foams, self-skinned foams, and slow-rebound foams. What I want to introduce below is that it belongs to a class of special polyurethane soft sponges, specific products such as pro (absorbent) water foams, non-yellowing foams and microcellular sheet sponges; these are also soft polyurethane foams, but they are soft Compared with high-quality foam, they all have special properties and applications, and are also indispensable products for people's daily life and industrial production. This article introduces the basic raw materials, production process and formula of these foams.First, the production formula and process of hydrophilic polyurethane flexible foam1. Its basic characteristics: It has a great affinity for water, absorbs water quickly and absorbs a large amount of water, has high softness (good hand feel), and good elasticity; the microscopic cells are delicate and have a mesh-like opening structure, and its excellent biological Affinity and blood compatibility broaden its wide application in cosmetics and medical fields.2. Current application scope:The characteristics of hydrophilic polyurethane foam also determine its good application in certain fields,(1) Nursing, physiological supplies such as mattresses for bedridden patients, accessories for sanitary napkins,(2) Medical accessories, surgical accessories (absorption of blood is similar to the function of cotton wool),(3) Traumatic dressing accessories, such as medical anti-inflammatory supplies such as band-aid, etc.(4) Daily cleaning blocks, bathing blocks, etc.,(5) Make-up care products, such as puffs, etc.(6) Absorption treatment materials in special fields.Polyurethane soft water-absorbing (absorbent) foam is mainly because its molecular chain itself has a similar segment structure containing ethylene oxide and the like; hydrophilicity; as long as polyester polyols and polyether polyols contain these or similar hydrophilic segments to a certain extent Degree, can make absorbent foam products.From the perspective of materials, there are polyether type and polyester type, but only according to the application of the product and the specific requirements to choose the appropriate production method and raw materials.3. Basic raw materials: The most commonly used include the following types,(1) The polyhydric alcohol part is mainly polyether polyol, that is, polyether polyol with high EO content, generally requires the content to reach more than 50%, both random and block copolymerization are possible, and there are many random in actual production. The functionality is generally 2-3, and the molecular weight is generally 1000-8000. Most commonly used is 2000-6000.(2), polyethylene glycol (PEG), molecular weight 1000-6000, most commonly used 1000-4000(3), polyester polyols, adipic acid series, polyols with high ethylene oxide structure, functionality 2-2.3, molecular weight 1000-2000(4), small molecular polyol (chain extender or cross-linking agent), commonly used are ethylene glycol, diethylene glycol, triethylene glycol, glycerin, TMP, etc.(5), isocyanate: here the isocyanate raw material part includes two typesTDI-100, TDI-80, HDI, IPDI, HMDISurfactant: Silicone oil series: L-580, Y10366, B8715, B-8123, etc.,Blowing agent: mainly water,Catalyst: Organotin, commonly used such as T-9, T-12, T-120, organic amines such as A-33, pentamethyldiethylenetriamine, diazabicyclo(2,2,2)octane Alkanes, etc.Hydrophilic resin: such as polyacrylates, hydroxy cellulose and so on.6. Basic production methodsAt present, there are two main methods of industrial production or development, one is the one-step method (the same as the ordinary PU foam production method), and the other is the two-step method, which is the prepolymer method.Here is a brief introduction to the basic process of the two-step polyether method (Dow Chemical has a variety of brands of such prepolymers in the international market, the NCO% content from 3%-13%)(1) Basic formula for prepolymer synthesisSmall molecule polyol 0-10TDI 20-50 (non-yellowing can use HDI, IPDI, HMDI, etc.)(2) The main points of prepolymer synthesis(A) The polyhydric alcohol part must be pre-heated at 120 ℃ under vacuum dehydration less than 0.05%,(B), low activity isocyanate needs to catalyze the reaction process,(C) The reaction temperature should not be lower than 80℃,(D) The viscosity should be controlled below 8000 mpa.s/25℃,(E) For different aliphatic isocyanate activities are different, the process conditions need to be adjusted.(F) The foam made with HMDI prepolymer is harder, the water absorption performance will be reduced, and the structure is highly open.Water above 10 (adjust according to requirements)Silicone oil L580 0.5-2.0(3), the main points of the manual foaming processThe stirring speed is 3000-5000 rpm, the stirring time is 4-8 seconds, and the control temperature is 25-70℃.(4), foaming requirements of casting machineThe metering gear pump requires high precision, the stirring speed is not less than 5000 rpm (the general thickness of the production sheet is 2-5mm, the width is 500mm), the production line requires a drying channel of generally 15-30 meters, and the release paper can be used repeatedly .The foam has an open-cell structure with a pore size of about 120-250 microns, and the usual density range is generally 100-200 (kg/m3).7. Basic physical properties of polyether hydrophilic foam(1) Water absorption performance

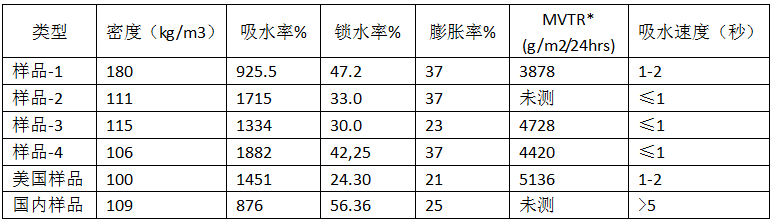

*Physical significance of the MVTR test index: The water permeability of the foam sheet per unit time area (water vapor permeability), the current European and American standard indicators are inconsistent, the method is also different, and cannot be converted, only samples can be taken Only the same method can be used for comparison, but the only method of water absorption index is basically the same.

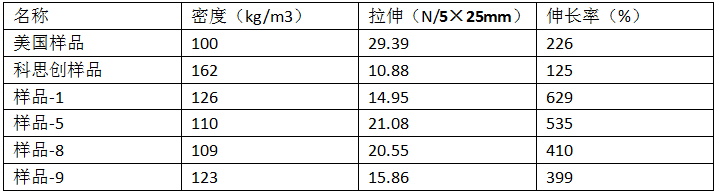

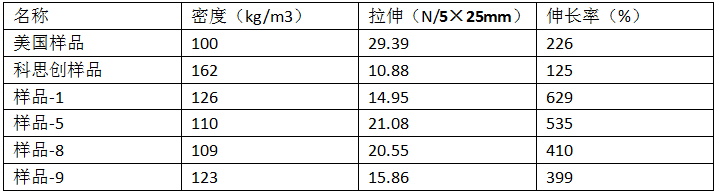

(2) Mechanical properties

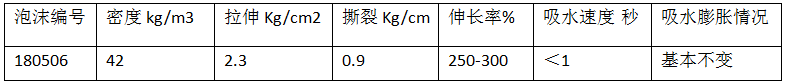

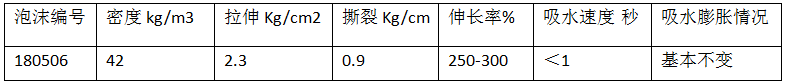

One obvious drawback of polyether-based water-absorbing foams is that the strength decreases significantly after absorbing water.For PEG, usually the molecular weight is increased and the water absorption is enhanced. It is appropriate to select a molecular weight of 1000-4000, otherwise the viscosity is too large.7. One-step foaming process of polyester hydrophilic foam() If it is produced by manual intermittent box foaming, it is basically the same as the ordinary polyester sponge foaming method. It should be noted that the surfactant silicone oil must be dedicated to polyester foam, the catalyst is organotin, organic amine It is usually appropriate to use a morpholine compound type catalyst.Physics and water absorption properties of polyester hydrophilic foam

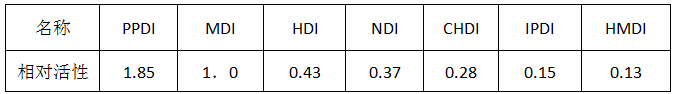

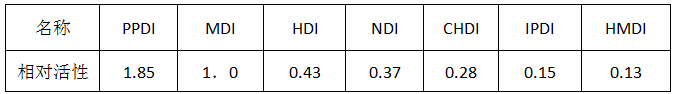

* The hydrophilic foam samples tested above have been treated. The treatment method is to soak the foam at a certain temperature and time.Second, the production formula and foaming process of the yellow foam soft foam1. At present, most of the flexible polyurethane foams (sponges) are easy to turn yellow, so now everyone said that yellowing resistant foam usually refers to the addition of antioxidants, heat stabilizers and light stabilizers during foam production. This can temporarily alleviate the rate of foam yellowing; easy yellowing is mainly because the benzene ring on the isocyanate can be gradually oxidized to a quinoid structure and yellow, and the foam macromolecular chain contains carbonyl, amino, and azo groups Chromophores such as alkenyl, alkenyl, etc. will selectively absorb when light enters, and emit a certain wavelength of light, causing a certain degree of yellowing of flexible foam.2. Effective solution to yellowingOne of the most effective ways is to use non-yellowing aliphatic isocyanates for foaming. Aliphatic isocyanates, such as IPDI, HDI, and HMDI, etc. The urethane bonds formed by these isocyanates are relatively stable. Fatty amines also do not have a benzene ring conjugated structure and do not form color-assisting groups, and the fatty amines themselves are not easily oxidized and are not likely to cause yellowing; therefore, the use of aliphatic isocyanates can significantly reduce the yellowing of the foam.3. Technical difficulties of aliphatic isocyanate foamingIn fact, many people have tried foaming production in this area for many years, but most people have encountered some technical difficulties, that is, aliphatic isocyanate is generally low in activity, and the foaming process is difficult to control. The range or the tolerance is very narrow, and it is difficult to make flexible foam that meets the requirements. The problems that often occur during the foaming process are: collapsed or partially collapsed, coarse foam, surface powdering, or closed cells, and more serious blocks The bubble shrinks.What needs to be explained here is that the foam sponge made of aliphatic isocyanate does not actually turn yellow at all, but it will oxidize and turn yellow very slowly under long-term light, water and heat conditions, but The yellowing rate of this type of foam is very low, it seems to people that it does not seem to turn yellow.4. Main raw materials and additivesPolyether polyol Polyether 210, 220, 560s, etc.High activity polyether polyol, molecular weight 4500-6000, such as 330N, 4701, etc.Small molecular polyols ethylene glycol, propylene glycol, butylene glycol, DEG, DPG,(2) Commonly used isocyanates are HDI, IPDI, HMDI,(3), catalysts, mainly two types of catalysts, one is organic amines, there are foam type and gel type, the main ones that can be used are: triethylenediamine, pentamethyldiethylenetriamine, pentamethyl Dipropylene triamine, triethylamine, diazabicyclo(2,2,2)octane, dimethylcyclohexylamine, 2,4,6-tris(dimethylaminomethyl)phenol, etc.; metals The main catalysts are: stannous octoate, organic bismuth, organic zirconium, organic titanium, organic cobalt.(4), surface active agent, mainly including high activity and medium activity, such as L-580, B-8123, B-8002, L-6900, DC-4900, DC-5169, B-8681, Y-10366 .(5), foaming agent, water and its physical foaming agentHigh activity polyether polyol 90-100Small molecule polyol 0-10Silicone oil B 8123 1.0-2.0The above amine catalyst 0.2-1.5Metal salt catalyst 0.5-1.75Aperture aid 0.5-3.0 (for high resilience, such as KF-28)Different people or regions may have different foaming process methods. The main reason is that the formulation, catalyst selection and dosage are not the same. The scheme or method is not unique. My method here is for reference only.Highly active polyether and other additives are mixed at room temperature in advance, then poured into IPDI and stirred for 6-15 seconds, then evenly poured into the pre-heated foaming box. After -30 minutes, the lump is pushed out and cured at room temperature for 24 hours before cutting. The cells are even and delicate, with high strength, good elasticity, no powdering, and generally no shrinkage. It needs to be pressed lightly for a small amount of shrinkage. Need special reminder not to use grafted polyether polyol.7. The difference in the reactivity between different aliphatic isocyanates and hydroxyl groups

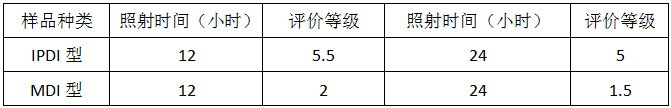

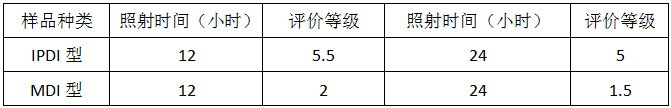

This is a technical difficulty in the production of aliphatic isocyanate foams. The key to the technology is the selection and adjustment of formulations and catalysts. There are still some technical know-how.8. Anti-yellowing performance of foamAccording to ASTM-D-1148 yellowing resistance test method, the test conditions are: 50 ℃, 300 watt hernia lamp illumination results:

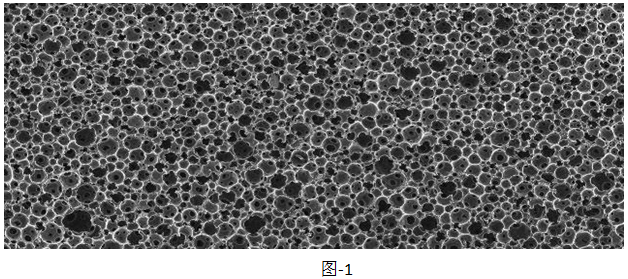

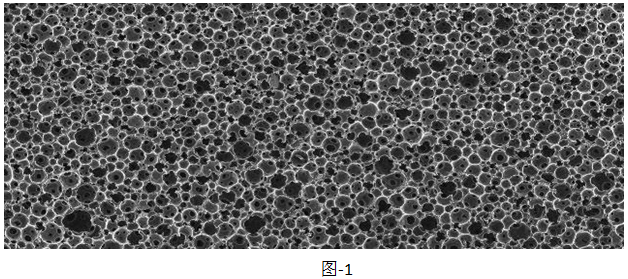

From the test results in the above table, it can be seen that the yellowing resistance of the aliphatic isocyanate foam is relatively excellent.Third, talk about the foaming production formula and process of microcellular flexible foam materials1. Application of microporous soft foamIt should be noted here that microcellular foam does not refer to microcellular PU elastomers (such as soles, insoles, high-speed rail gaskets, tires, automobile springs and other foams), but a soft, high-density polyurethane foam sheet. It belongs to special polyurethane soft foam. The typical cell structure is shown in Figure-1.

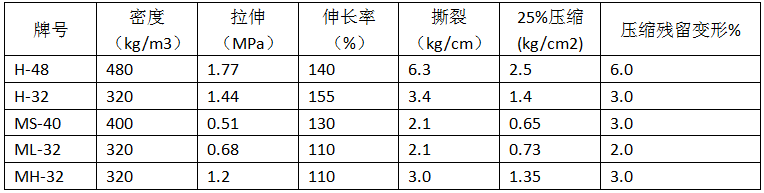

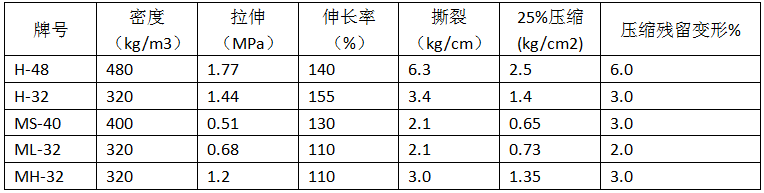

This polyurethane flexible foam sheet has been widely used in communications, computers, household appliances, digital products, other electronic products, shoe materials, medical equipment, hardware, etc. as a seal, shock absorption, cushion material.High sealing, high energy absorption (high cushioning), high dimensional stability.Excellent resistance to compression deformation, water resistance, high temperature resistance, aging resistance, environmental protection and no pollution.3. Density and specificationsThe density of this flexible foam is generally between 240-480kg/m3, the pore size of the foam is generally 100-250 microns, different applications or different products have different density, thickness and hardness, and the opening and closing of microcellular foam Pore degree, etc., the performance is also different; such as high foam closed cell sealing, waterproof, dustproof effect is outstanding; high micro cell opening rate is good elasticity, small compression deformation type; thickness is generally from 0.1-6mm specifications There are a lot of specific specifications.4. Similar domestic and foreign typical productsThere are the PORON brand of Rogers, and similar products of Inoue Poron in Japan, SK and GMC in South Korea.Typical physical properties of several microcellular soft foam sheets (take poron as an example)

6. Composition of materials and formula(1), the basic composition of the hydroxyl component: polyester polyol 16-30Polymer polyether polyol 20-40Small molecule polyol 1.5-16Surfactant (silicone oil) 0.1-1.0Color paste 0.5-3.0 (mainly carbon black paste)Solid powder 0-20 (silica, aluminum hydroxide,)Flame retardant amount (according to requirements)Organic amine catalyst 0-0.5(For different specifications of products or brands, the ratio of the above polyols is different (mainly by adjusting the ratio of different polyols, the equivalent weight, the molecular chain structure to adjust the relevant physical properties of the microcellular foam to meet different use).(2), the composition of the isocyanate component:Isocyanate foaming index: 1.0This foaming process is different from the ordinary water chemical foaming or ordinary physical foaming agent (such as methylene chloride, etc.) foaming process, but uses a permanent gas injection foaming method, the basic production process uses multi-component low pressure It is mechanically cast on the release paper of the conveyor belt and continuously scraped to a uniform thickness and then cured by a constant temperature gel of the drying tunnel. The product is rolled into a roll and then cured. The unique foaming process determines the outstanding performance of the material.The organometallic salt catalyst suitably controls the reaction rate.Strict temperature control is also an important factor in controlling product quality.8. Post-processing of microcellular foamIt mainly uses some bright surface polishes, often acrylic paints.

We respect originality. The text picture material, the copyright belongs to the original author. Some articles could not be contacted with the original author due to various reasons. If the copyright issue is involved, please contact the original author to deal with it immediately.

Factory address: Longzhen Avenue, Longshan Industrial Zone, Cixi, Ningbo

Marketing Center: 1308 Yaojiang Xindu, Hongtang Street, Jiangbei, Ningbo

Phone: +860574-86501282-0

83096225 83096226

Fax: +860574-86501283

Website: http://zy-pigment.en.alibaba.com/

![]()

![]()