Color paste, as the main auxiliary agent used in polyurethane foaming, is widely used in various polyurethane materials. Our factory, as a professional polyurethane color paste manufacturer in East China, produces color pastes with high color concentration, good fluidity, large additions without affecting foaming, bright colors, and strong weather resistance......

1、Polyether

Polyether as the main raw material reacts with isocyanate to form urethane, which is the skeleton reaction of foam products. In the case of the same functionality, when the molecular weight increases, the tensile strength, elongation and resilience of the foam increase, and the reactivity of the same polyether decreases; in the case of the same equivalent value (molecular weight/functionality), the functional When the degree is increased, the reaction is relatively accelerated, the degree of cross-linking of the generated polyurethane is increased, the foam hardness is increased, and the elongation is decreased. The average off energy of the polyol should be above 2.5. If the average off energy is too low, the foam will recover poorly after compression.

If the amount of polyether is large, it is equivalent to the reduction of other raw materials (TDI, water, catalyst, etc.), which is easy to cause foam products to crack or collapse.

If the amount of polyether is small, the foam products are harder, the elasticity is reduced, and the feel is not good.

2、Blowing agent

In general, when manufacturing polyurethane foam with a density greater than 21, only water (chemical foaming agent) is used as a foaming agent, and low-boiling compounds such as dichloromethane (MC) (physical development) are used in low-density formulas or ultra-soft formulas. Foam) as an auxiliary foaming agent.

Auxiliary blowing agent will reduce the density and hardness of the foam. Because its gasification absorbs part of the reaction heat, it will slow down the curing, and the amount of catalyst needs to be increased. Due to the absorption of heat, the danger of burning the core is avoided.

The foaming capacity can be expressed by the foaming index (the equivalent number of water or water used for 100 parts of polyether): m--- amount of foaming agent

Foaming index IF=m(water)+m(F-11)/10+m(MC.)/9(100 points polyether)

Water as a blowing agent reacts with isocyanate to form urea bonds and emit a large amount of CO2 and heat, which is a chain growth reaction.

The amount of water is large, the foam density is reduced, and the hardness is increased. At the same time, the pillar of the cell becomes smaller and weaker, which reduces the bearing capacity, and it is easy to collapse and crack. The amount of TDI consumed increases, the amount of heat released is more, and it is easy to heartburn. If the amount of water exceeds 5.0 parts, a physical blowing agent must be added to absorb part of the heat to avoid the scorching phenomenon.

With less water, the amount of catalyst decreases accordingly, but the density increases.

4、catalyst

Amine: A33 is generally used. Its function is to promote the reaction of isocyanate and water, adjust the foam density, bubble opening rate, etc., mainly to promote the foaming reaction.

Aminopoly: the foam product cracks, and there are holes or holes in the foam

Less amine: the foam shrinks and closes the cell, and the foam product has a thick bottom.

Tin: Tin-9 octoate is generally used; T-19 is a gel reaction catalyst with high catalytic activity, mainly to promote the gel reaction, that is, the late reaction.

Tin more: fast gelation, increased viscosity, poor resilience, poor permeability, resulting in closed cells. If the dosage is properly increased, a good open-cell foam can be obtained, and further increasing the dosage will gradually make the foam tight, so that it shrinks and closes the cell.

Less tin: Insufficient gel, cracking caused by foaming process. There are cracks on the edge or top, and there are blanking and burrs. Reducing amine or increasing tin can increase the strength of the polymer bubble film wall when a large amount of gas occurs, thereby reducing hollowing or cracking.

Whether the polyurethane foam has an ideal open-cell or closed-cell structure mainly depends on whether the gel reaction rate and gas expansion rate during foam formation are balanced. This balance can be achieved by adjusting the type and amount of tertiary amine catalyst and foam stabilization and other additives in the formulation.

5、Foam stabilizer (silicone oil)

Foam stabilizer is a type of surfactant, which can make polyurea well dispersed in the foaming system, play the role of "physical cross-linking point", and can significantly increase the early viscosity of the foam mixture to avoid cracking. On the one hand, it has an emulsifying effect, which enhances the mutual solubility between the components of the foam material. On the other hand, the addition of silicone surfactants can reduce the surface tension r of the liquid. The air in the raw material is easier to nucleate during the mixing process, which helps to generate fine bubbles, adjust the size of the foam pores, control the cell structure, and improve the foaming stability; prevent the foam cells from collapsing and breaking, so that the foam wall has Elasticity, control foam pore size and uniformity. It stabilizes the foam in the early stage of foaming, prevents the co-foaming of the foam in the middle of firing, and connects the cells in the late stage of foaming. Generally, the more the amount of blowing agent and POP, the greater the amount of silicone oil.

High dosage: It will increase the elasticity of the foam wall in the later stage, and it is not suitable for rupture, and the cell is fine. Causes closed cells.

Low dosage: The foam bursts, collapses after hair onset, the pore size is large, and it is easy to foam.

6、Influence of temperature

The foaming reaction of polyurethane accelerates as the temperature of the material rises. In sensitive formulations, it will cause the risk of scorching and fire. The temperature of the polyol and isocyanate components is generally kept constant. When foaming, the foam density decreases and the material temperature increases accordingly. With the same formula, the material temperature is the same as the summer temperature is high, and the reaction speed is accelerated, resulting in a decrease in foam density and hardness, an increase in elongation, and an increase in mechanical strength. In summer, the TDI index can be appropriately increased to correct the decrease in hardness.

7、Influence of air humidity

Increased humidity, due to the reaction of the isocyanate groups in the foam with moisture in the air, resulting in a decrease in hardness, so the amount of TDI can be increased appropriately when foaming. If it is too large, the maturation temperature will be too high and cause heartburn.

8、Influence of atmospheric pressure

The same formula, foaming at high altitudes, the density of foam products is small.

Note:

1. During the formation of the foam plastic, the gel reaction and the foaming reaction occur at the same time, but there is competition between the reactions. Generally, the foaming reaction speed is greater than the gel reaction speed.

Gel reaction-carbamate formation reaction, (reaction with -OH)

Foaming reaction-refers to the reaction with the participation of water, generating urea and generating bubbles

2. Nucleating agent-substances that cause the formation of bubbles, such as fine solid particles in the system, liquid foam stabilizers or fine bubbles originally dissolved in the material, etc.; including air or nitrogen, carbon dioxide dissolved in polyols and isocyanates , Foam stabilizer, carbon black and other fillers. However, the gas generates more bubbles in the material; the more stable and more fine the cells are. The number of bubbles formed in the foaming system and the size of the cells in the foam plastic depend on the effect of the external nucleating agent; there are many nucleating agents, many bubbles, and small cells.

When the temperature rises, the solubility of the gas in the liquid decreases, so more bubbles will form or the previous start will grow. Milky white time is long, which is conducive to the growth of large bubbles.

Increasing the amount of catalyst can shorten the milking time. Due to the competitive reaction of gel reaction and bubble formation, fine-pore foam can be obtained.

3. Whether the foam has an ideal open-cell or closed-cell structure mainly depends on whether the gel speed and the gas expansion speed in the foam formation process are balanced. This balance can be achieved by adjusting the type and amount of additives such as tertiary amine catalysts and foam stabilizers in the formulation.

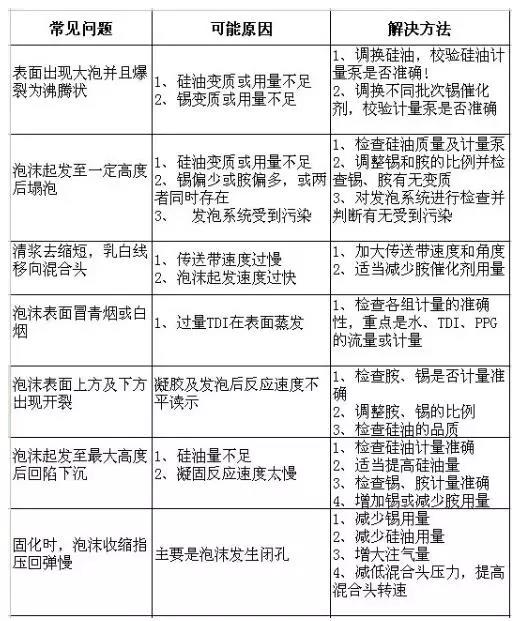

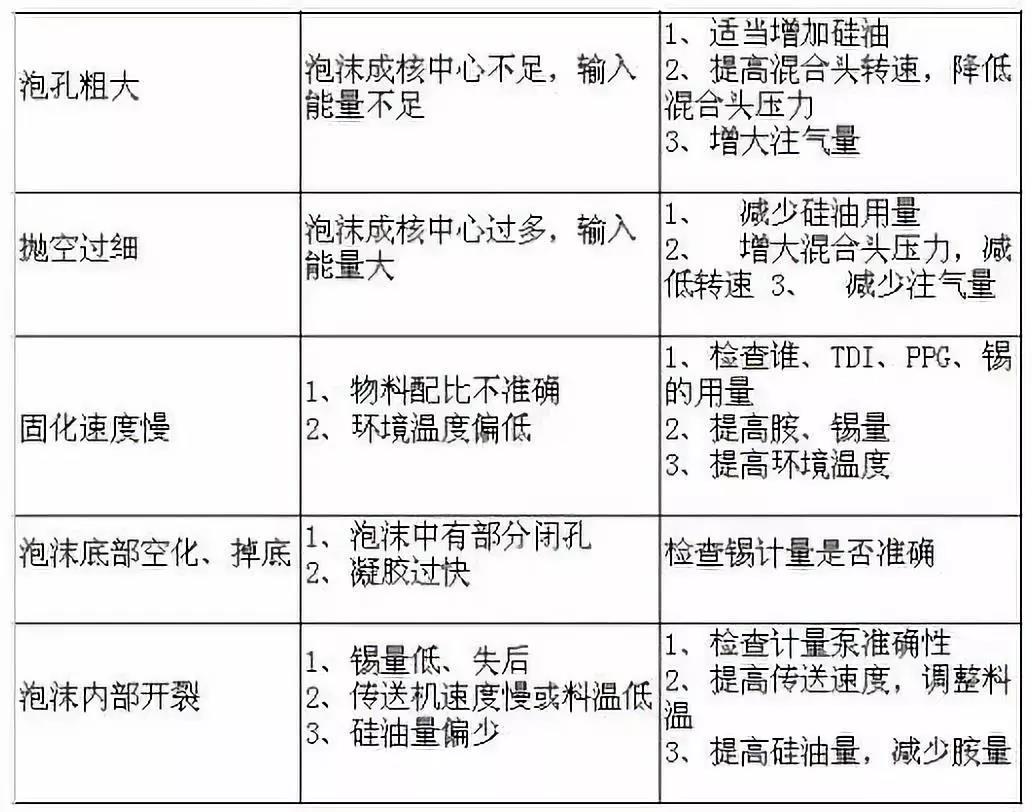

Common problems and solutions in soft foam production

![]()

![]()

We respect originality. The text picture material, the copyright belongs to the original author. Some articles could not be contacted with the original author due to various reasons. If the copyright issue is involved, please contact the original author to deal with it immediately.

工厂地址:宁波市慈溪龙山工业区龙镇大道

营销中心:宁波市江北洪塘街道姚江新都1308

电 话: +860574-86501282-0

83096225 83096226

传 真: +860574-86501283

网 址:http://zy-pigment.en.alibaba.com/